Chama came to us with a vision of a premium portable chair that meets the needs of discerning outdoorsmen. As hunters themselves, they knew the market had not delivered a rugged and reliable solution that could last more than a season or two. We designed a robust outdoor chair with thick aircraft-grade aluminum supports and a unique hub system that allows the chair to silently rotate 360°.

For hunters and fishermen, a rotating chair is essential. They need to react to the uncertainties of the environment without causing a ruckus fumbling around with positioning and rebalancing. Swivelling hunting chairs exist, but are noisy or unreliable. Engineering makes the difference for the Chama Chair, which rotates on a silent self-lubricating thrust bearing. Chama came to us with a concept that could make its mark in the market, but needed a design as bold as their vision.

For hunters and fishermen, a rotating chair is essential. They need to react to the uncertainties of the environment without causing a ruckus fumbling around with positioning and rebalancing. Swivelling hunting chairs exist, but are noisy or unreliable. Engineering makes the difference for the Chama Chair, which rotates on a silent self-lubricating thrust bearing. Chama came to us with a concept that could make its mark in the market, but needed a design as bold as their vision.

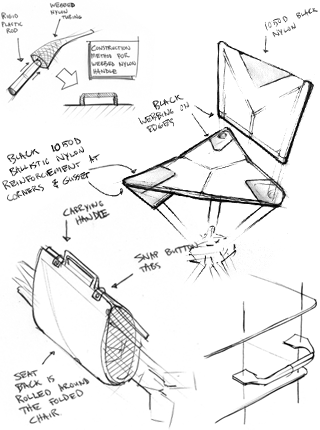

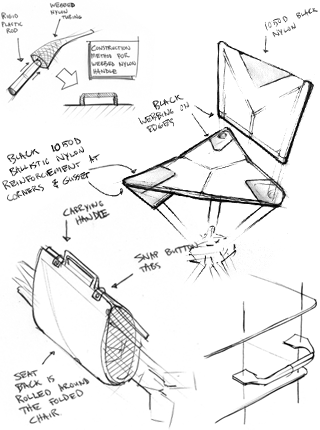

Starting from their initial proof-of-concept prototype, we refined each component for greater usability, function, structural resilience, and aesthetic impact. Sketch ideation, CAD, and several prototypes helped polish the various mechanisms, preparing us for manufacturing.

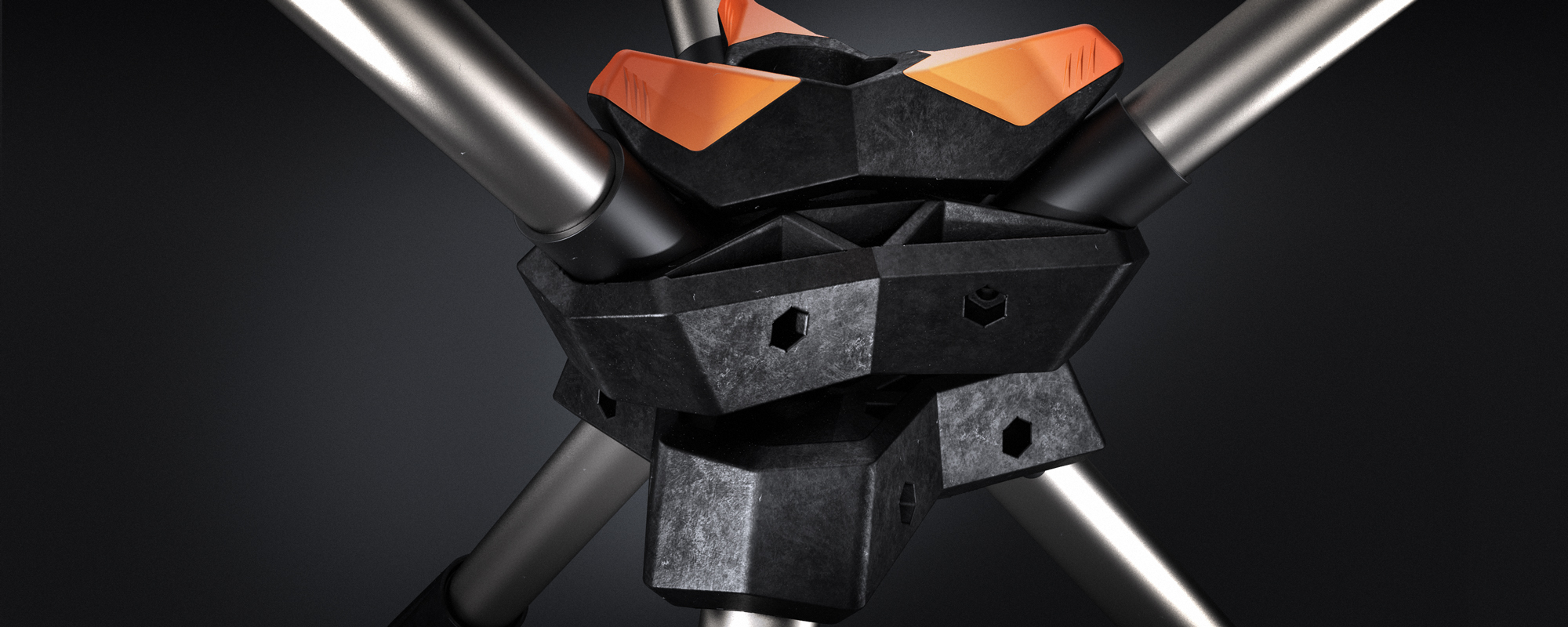

The central hub joins the leg and arm tubes, locks the arms into place for deployment, and enables the silent 360 degree rotation between top and bottom. The upper knob with orange overmolded grips rotates 60 degrees to transition from locked to unlocked position. In the locked position, it supports the arms and weight on the seat up to 250 lbs. Out of several possible mechanisms, we found this to be the most intuitive, efficient, and reliable solution. Lab testing of machined prototypes confirmed the design’s robustness before final tooling.

Uneven terrain is a given in the outdoors. Four-legged chairs are always at a disadvantage, and never able to be properly planted. Like a camera tripod, the Chama Chair has three legs, each of which is adjustable to any position within range. With a weight target of 250lbs, we paid a lot of attention to the leg locking mechanism. Aside from reliable, it had to be an enjoyable and maintenance-free experience. The final design uses a low-profile threaded collar to drive a cylindrical wedge between the outer and inner leg tubes. At the end of each leg is a swivelling foot, with a base wide enough to keep from sinking into soft ground.

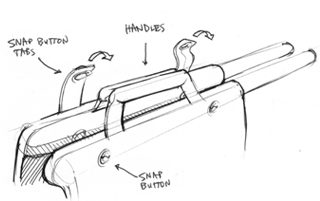

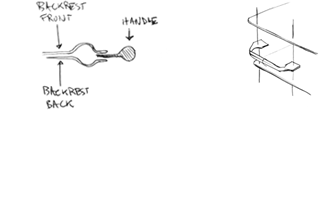

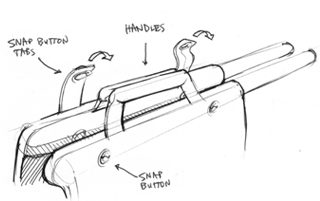

The joint at the top of the Chama Chair’s arms serve dual functions. We wanted the seat fabric to be easily removed for cleaning or storage. We also needed a dead-simple way to quickly attach or removed the optional backrest. Our development process produced the final design, which features an obround collar that holds the seat fabric securely but instantly releases it when the seat is pulled from the proper direction. This collar surrounds a secondary tube into which the arms of the backrest are inserted. Snaps on the ends of the arms secure the backrest into place and take seconds to remove.

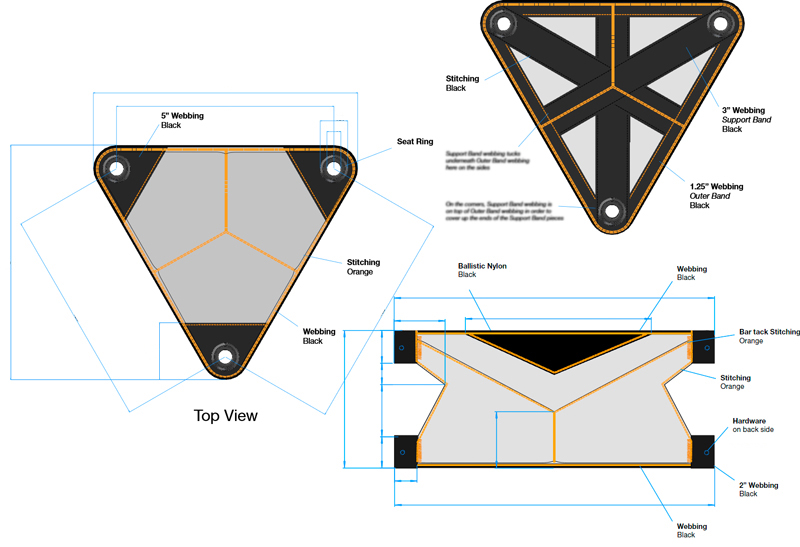

In addition to the hardware for the chair, we also helped develop the soft goods components. This was an exercise in material selection and careful application. We had to achieve the strength to meet Chama’s weight goals, ensure longevity in harsh environments, and, of course, provide long-lasting comfort for the patient hunter.