Pecos Outdoor Table – 2021

The team at Pecos Outdoor came to us with a mission: create a bombproof outdoor table built to last a lifetime.

Fed up with flimsy tables that barely last a season, they tasked us to prioritize rigidity, durability, and a premium user experience. The design criteria necessitated careful engineering from the outset, choosing materials and manufacturing processes that would facilitate the end goal. Keeping production within the US further constrained our options for processes and cost. With a multi-staged design approach we bridged from initial concepts to side-by-side development with US partners. The result is a table that stands up to the test – a literal 3,000 lbs of force.

There’s more than one way to dice a tomato – or design a table. We explored several approaches to analyze the ramifications of sourcing, manufacturing, assembly, and user experience. While some approaches had merits in certain categories, they potentially lacked in others. We explored these nuances with Pecos Outdoor to help them define and solidify their vision.

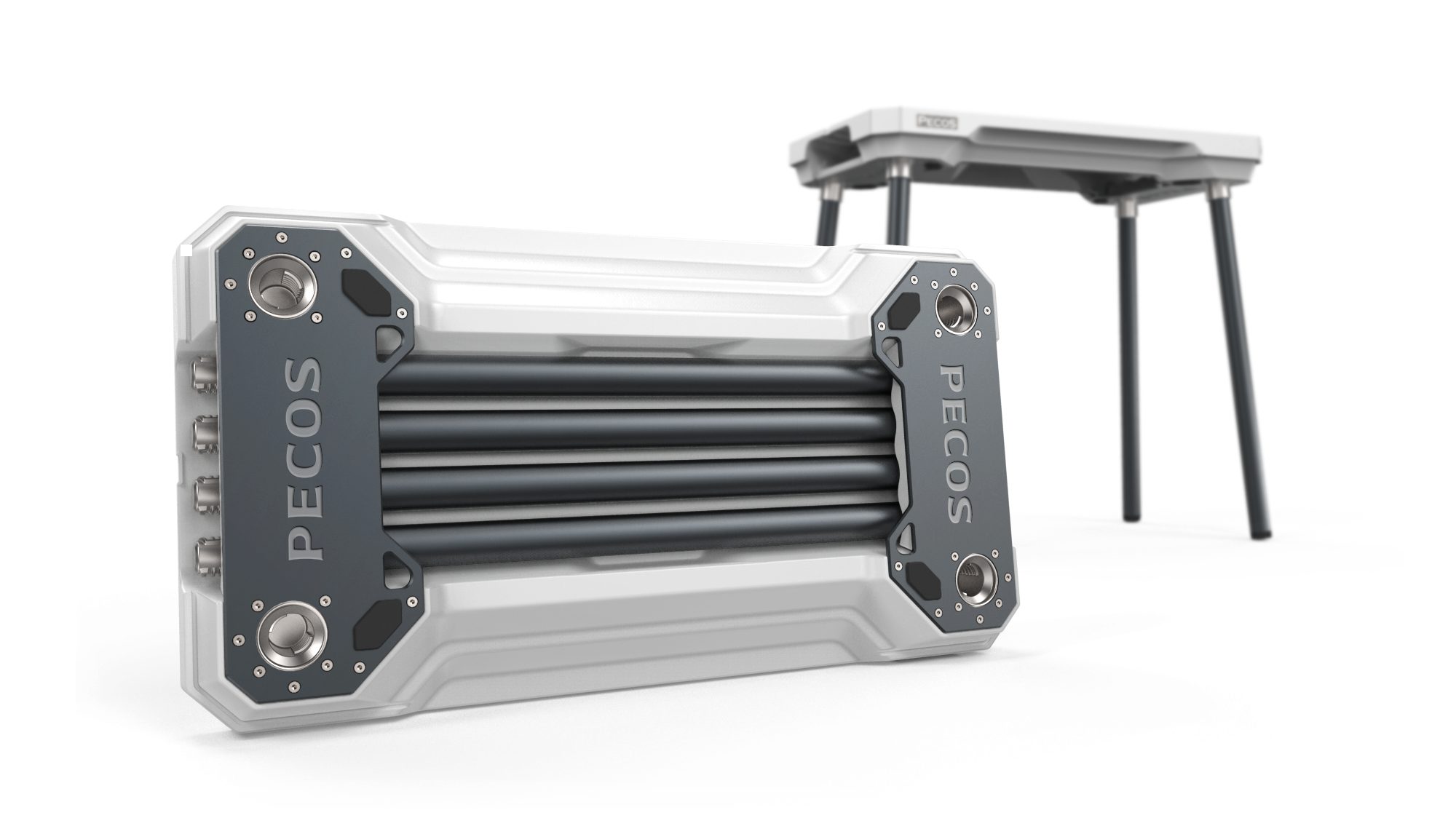

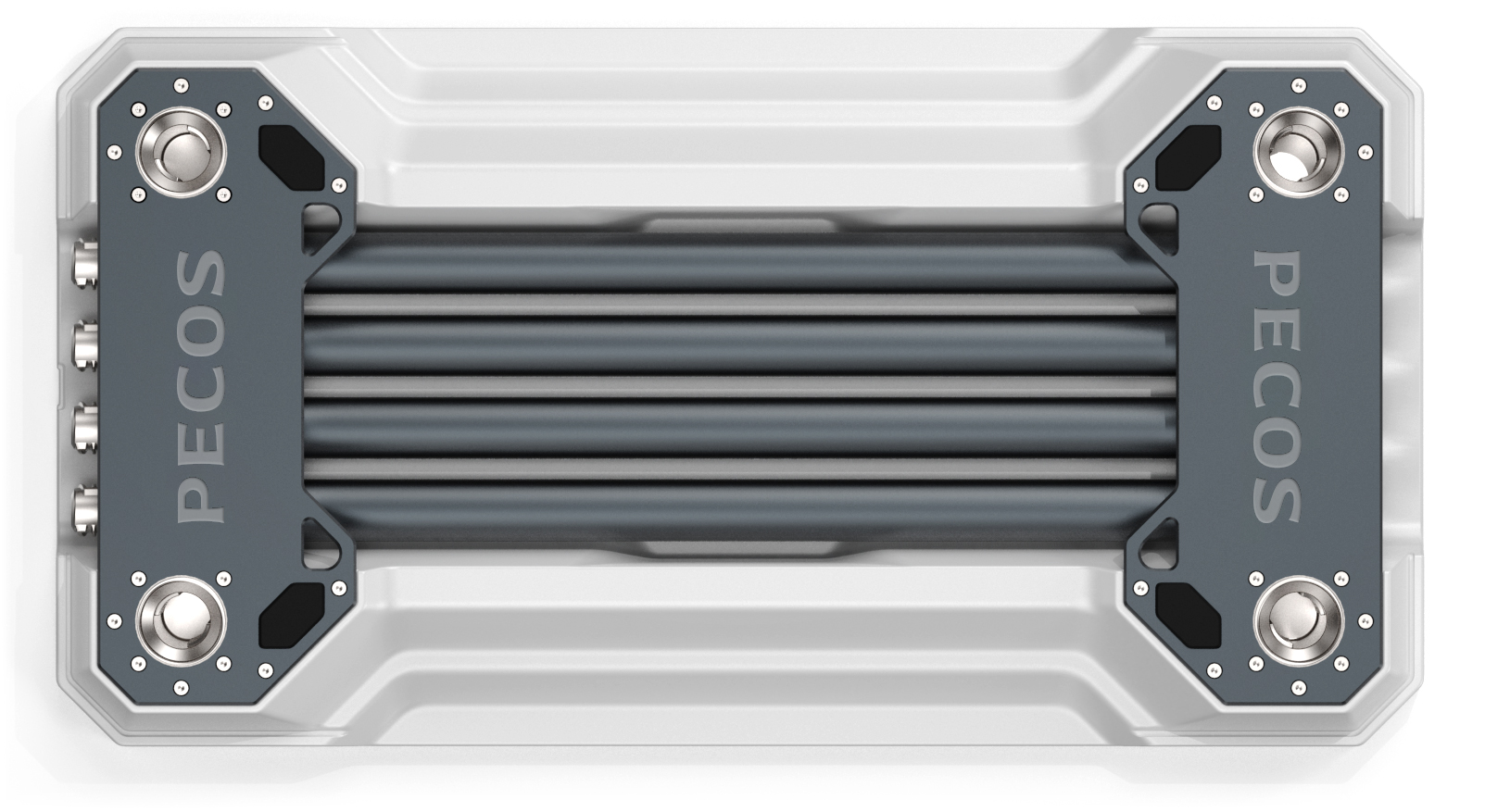

Ultimately, rotomolding was the best choice for production. The table body is formed of food-grade HDPE and the interior cavity is filled with PU foam for high stiffness with low added weight. While the rotomolding process has limitations and requires special concessions, the result is a solid foundation onto which the remaining parts can be assembled. Two die-cast plates rigidly tie the die-cast leg sockets together and to the table body. The complete table is solid, sturdy, and silent; a result of considered design choices.

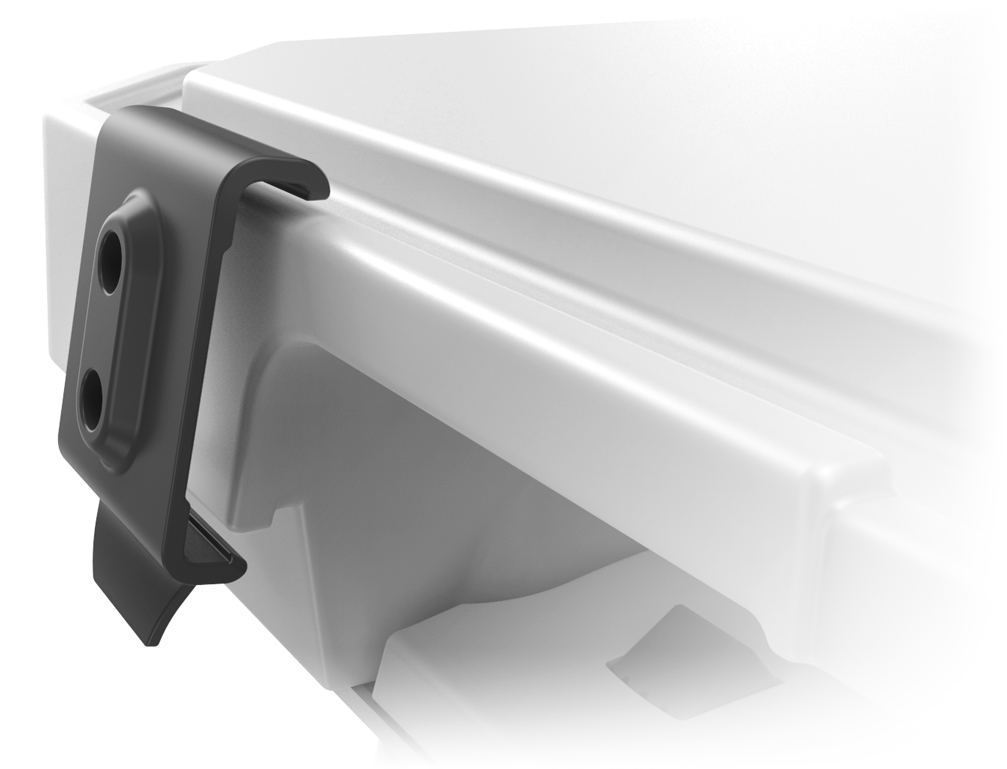

The bedrock of the Pecos Table’s sturdy design is the leg system. The legs slide and stow within the table body and are kept in place by a satisfyingly clicky retention mechanism we designed and engineered. Upon deployment, the caps of the legs secure to the underside sockets with a quick quarter-turn motion. All leg joint parts are die-cast for maximum rigidity and durability.

The threads of the leg joints are entirely custom and feature multiple innovations. The unique threads create a seamless experience for the user and became a core part of Pecos Outdoor’s patentable IP. We designed and engineered the entire system and worked closely with the die-cast production engineers to bring the design to market.

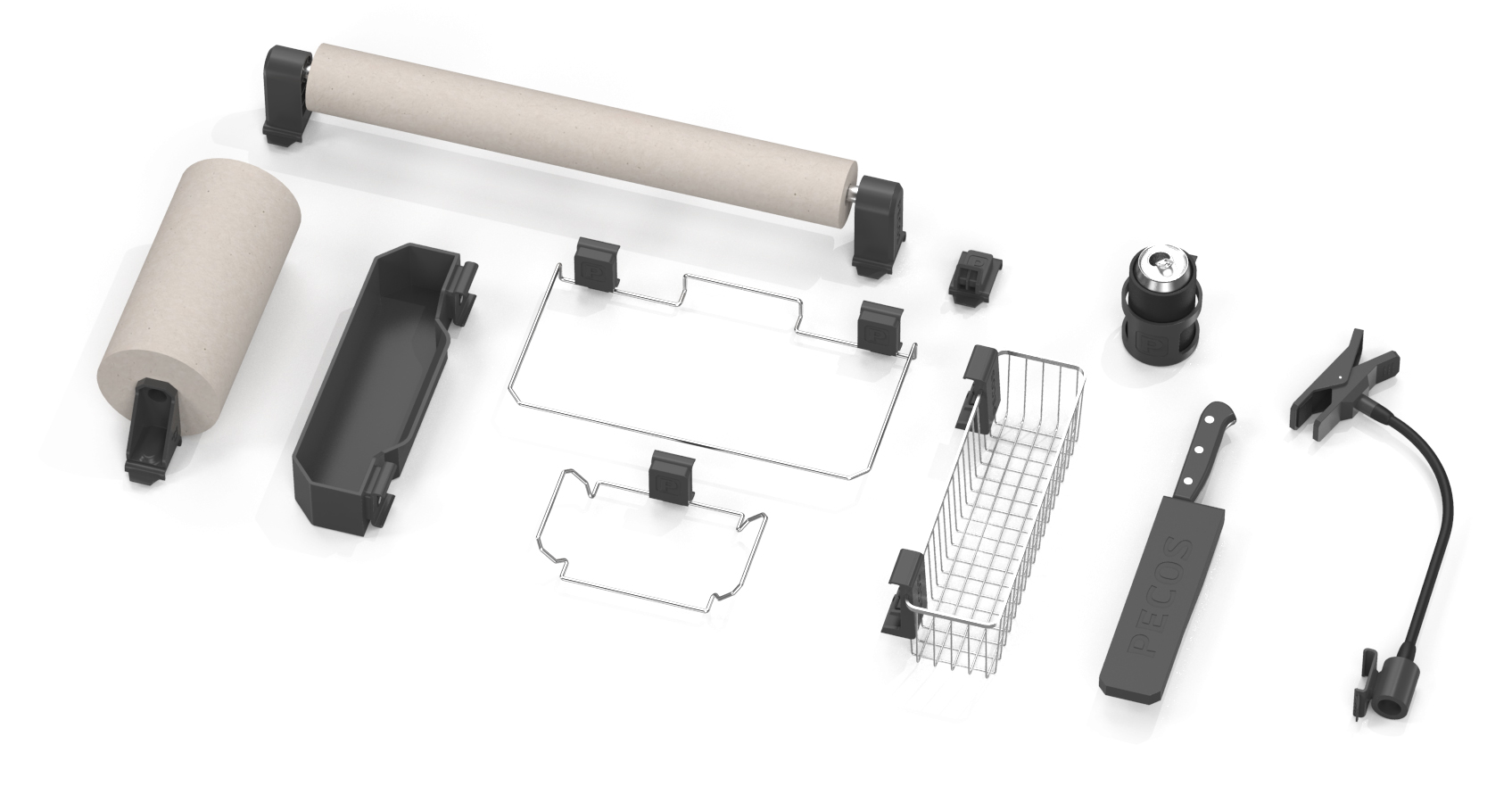

Flat and clean work surfaces are a rare thing in the wild. Pecos Outdoor wanted to supply that, and go beyond to create a mobile workspace for food prep. We developed a system of accessories that snap onto the outer rim of the table and extend the functionality from simple surface to practical kitchen.